ATEXON - Automatic Spark Detection

Combustible dust-air mixtures often occur in pneumatic and mechanical transfer systems handling particulate solids, such as dust collection systems. Vessels receiving this material are at risk of dust explosions. Ignition sources generated in other areas of the process are often carried to these collection areas through the transfer duct, chute or conveyor where they can find the right conditions to initiate the explosion.

A dust explosion can cause an over-pressure event up to 10 bar if unmitigated. Such overpressures from dust explosions can rupture filters and dust containers and put employees safety at risk.

Atexon® spark detection and extinguishing systems from Helios Fire Systems are designed to protect industrial processes by helping reduce the risk of ignition sources such as burning embers from reaching protected equipment. The system detects sparks and extinguishes them automatically without interrupting process operations. The small amount of water extinguishant used, approximately five lighters, will greatly limit any interruption to filters or other production machines. Once the ignition source has been mitigated, the system automatically resets to normal operations and is ready to extinguish new ignition sources.

Application in Industry

- Mechanical wood working industry

- Wood processing plants

- Pellet manufacturing

- Crushers

- Elevators

- Sawmills

Features

- Milliseconds response time

- Can extinguish detected ignition sources using only a small amount of water

- Signal router controls and monitors the extinguishing event

- System monitored by control panel

- Output alarms using siren AND strobe light

- Controller stops the fans in case of overheating or a spark shower

- Pressure booster controller supervises the water pump and the heat tracing cables

- The pressure booster station ensures the delivery pressure and prevents pockets of air in the extinguishing water

Products

A.T.F.S.

Targeted Fire Suppression

Flamescan

Early Warning Flame Detection

AMFE

Miniature Fire Extinguisher

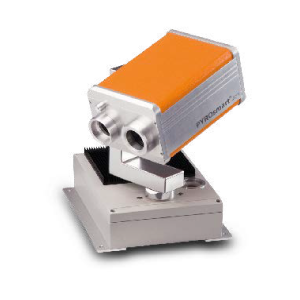

Pyrosmart

Early Warning Targeted Detection

I-Detect

Infrared Early Fire Detection

Fire Mist

High Pressure Mist